Camshaft and Lifters

Mock up mode is coming along. Willie walks through file fitting rings in a few easy steps. Kevin gets technical about ring gaps and introduces the Crower Roller Camshaft.

Mock up mode is coming along. Willie walks through file fitting rings in a few easy steps. Kevin gets technical about ring gaps and introduces the Crower Roller Camshaft.

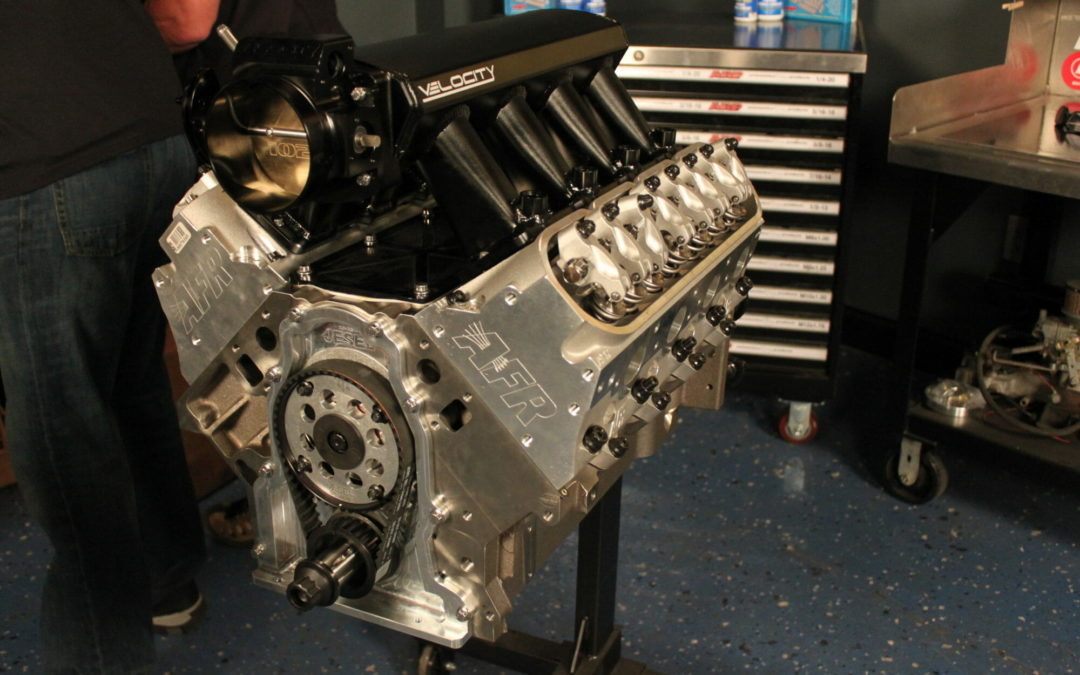

The guys outfit the engine with an AFR Mongoose LS3 head and discuss best practices for torquing and checking push rod lengths.

Willie and Kevin check piston to valve clearance in anticipation of starting the final assembly.

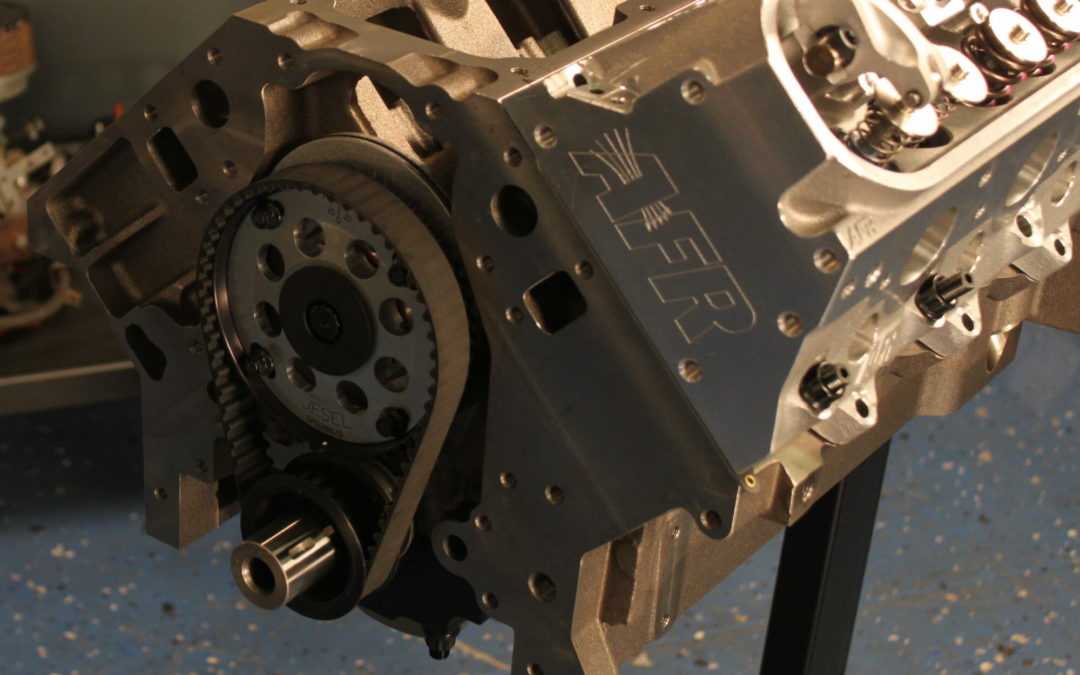

Willie and Kevin install a Jesel belt drive for on-the-fly cam timing adjustments; insert the correct length push rods; and cap it all off with a shaft rocker arm system.

The guys shift their focus to airflow, installing a Top Street Performance High Rise intake and capping it with a 102mm throttle body.

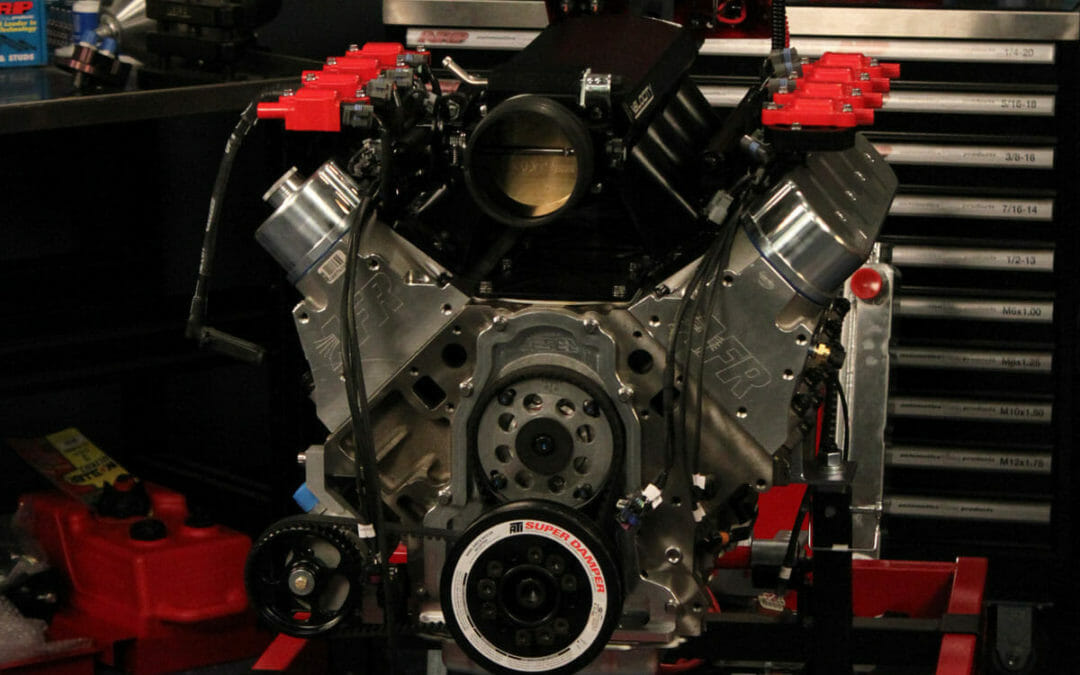

Addressing the fuel system, Willie and Kevin install Top Street Performance fuel rails and a set of injectors from Fuel Injector Connection.

Willie and Kevin install and explain the benefits of an AVIAID dry sump oil system and finish the install with an ATI balancer.

The guys tend to the electrical systems of the motor by installing SMP sensors and a custom wiring harness, so everything can talk to the computer.

It’s finally time for all the hard work to pay off, but first there are some final touches to be made. Once everything’s in place, the guys start the engine for the first time!

The day everyone’s been waiting for is here, and it’s time to see what kind of power this engine will put out. At the engine dyno, Willie and Kevin make final adjustments and finally get to hear what the engine sounds like at 7000 RPMs.